Perfectly Smooth Walls: A Skim Coating Tutorial

Hi friends, Emmett here! Sarah mentioned she gets a lot of questions about drywall finishing, the texture of the walls in our home, and how to achieve those perfectly smooth walls. I’ve been plugging away on our home office renovation and of course- the designer (aka my wife) requested a level 5 drywall finish… which basically means she wants perfectly smooth walls. That’s always her preference, if possible. I thought it would be helpful to share some visuals and tips for achieving that super smooth finish with a quick skim coating tutorial. Click through for some helpful tips, finishing vocab (to pass along to your contractor, if you’re using one), and some tricks for achieving quality craftsmanship.

Hi friends, Emmett here! Sarah mentioned she gets a lot of questions about drywall finishing, the texture of the walls in our home, and how to achieve those perfectly smooth walls. I’ve been plugging away on our home office renovation and of course- the designer (aka my wife) requested a level 5 drywall finish… which basically means she wants perfectly smooth walls. That’s always her preference, if possible. I thought it would be helpful to share some visuals and tips for achieving that super smooth finish with a quick skim coating tutorial. Click through for some helpful tips, finishing vocab (to pass along to your contractor, if you’re using one), and some tricks for achieving quality craftsmanship.

When is skim coating handy or necessary? If you’re trying to smooth existing drywall, cover wallpaper texture, or are repairing drywall skim coating is your best bet. In our case, the existing drywall in Sarah’s office wasn’t in great shape and had both texture, wallpaper removal lines as well as a two inch wide stripe around the room from removing the chair railing. Half of the sheet rock in the room is new and the other half is existing, so my goal was to skim coat everything to match, resulting in a level 5 finish.

When is skim coating handy or necessary? If you’re trying to smooth existing drywall, cover wallpaper texture, or are repairing drywall skim coating is your best bet. In our case, the existing drywall in Sarah’s office wasn’t in great shape and had both texture, wallpaper removal lines as well as a two inch wide stripe around the room from removing the chair railing. Half of the sheet rock in the room is new and the other half is existing, so my goal was to skim coat everything to match, resulting in a level 5 finish.

First up… let’s chat about the finishing levels, which also kind of translates to the phases if you’re going for that smooth look. There are 5:

First up… let’s chat about the finishing levels, which also kind of translates to the phases if you’re going for that smooth look. There are 5:

- Level 0 // This means there is no finishing that has been completed. At this level, the sheetrock is just hanging on the wall or ceiling, with nothing done to it. Screws and joints exposed.

- Level 1 // Level one means that the joint tape has been installed and mudded, but nothing else has been completed.

- Level 2 // This level means that you have skim coated a thin layer of joint compound over the tape and covered the drywall screws. If you’re planning to tile, it’s fine to stop at this level. Many tract homes receive this level in the garage.

- Level 3 // This stage indicates a solid coat of joint compound has been installed to the tape and screws. Walls that will receive a heavy texture (like knockdown), often stop at this level. Level 3 finishing is meant for a highly textured wall outcome.

- Level 4 // This is your classic drywall finish… the standard or norm. Level 4 receives an additional coat of joint compound to cover the tape, seams, screws, and has been sanded in between. This is the most common finish and can be painted or wallpapered nicely.

- Level 5 // As you might have guessed, Level 5 is the gold standard. It’s as smooth as you can get, or the highest finish possible. There are no bumps, no texture, and it’s achieved by multiple skim coat layers that are finished with a good sanding.

If you’re striving for a five finish, this is what I used to achieve that…

If you’re striving for a five finish, this is what I used to achieve that…

- Joint Compound (I like ultraweight)

- Roller with a 3/4″ Nap, pictured above (the nap is important because it provides texture and rolls it on thick)

- Skimming Blade (I have a 32″ for walls and a 12″ & 14″ for working around outlets and windows)

- Sanding Pads (I use 220 and 180)

- Drill with Mixer Attachment

- Bucket with Lid (to keep it from drying out in between passes)

Before we get started… the longer the skim coating blade, the flatter your finish will be. For scale, here I am with my 32″ skim coating blade. If your wall is very unlevel or uneven, you’ll probably want to begin with a 24″ blade, and hit the problem areas first before moving to the 32″. Ready to walk through the skim coating process?

Before we get started… the longer the skim coating blade, the flatter your finish will be. For scale, here I am with my 32″ skim coating blade. If your wall is very unlevel or uneven, you’ll probably want to begin with a 24″ blade, and hit the problem areas first before moving to the 32″. Ready to walk through the skim coating process?

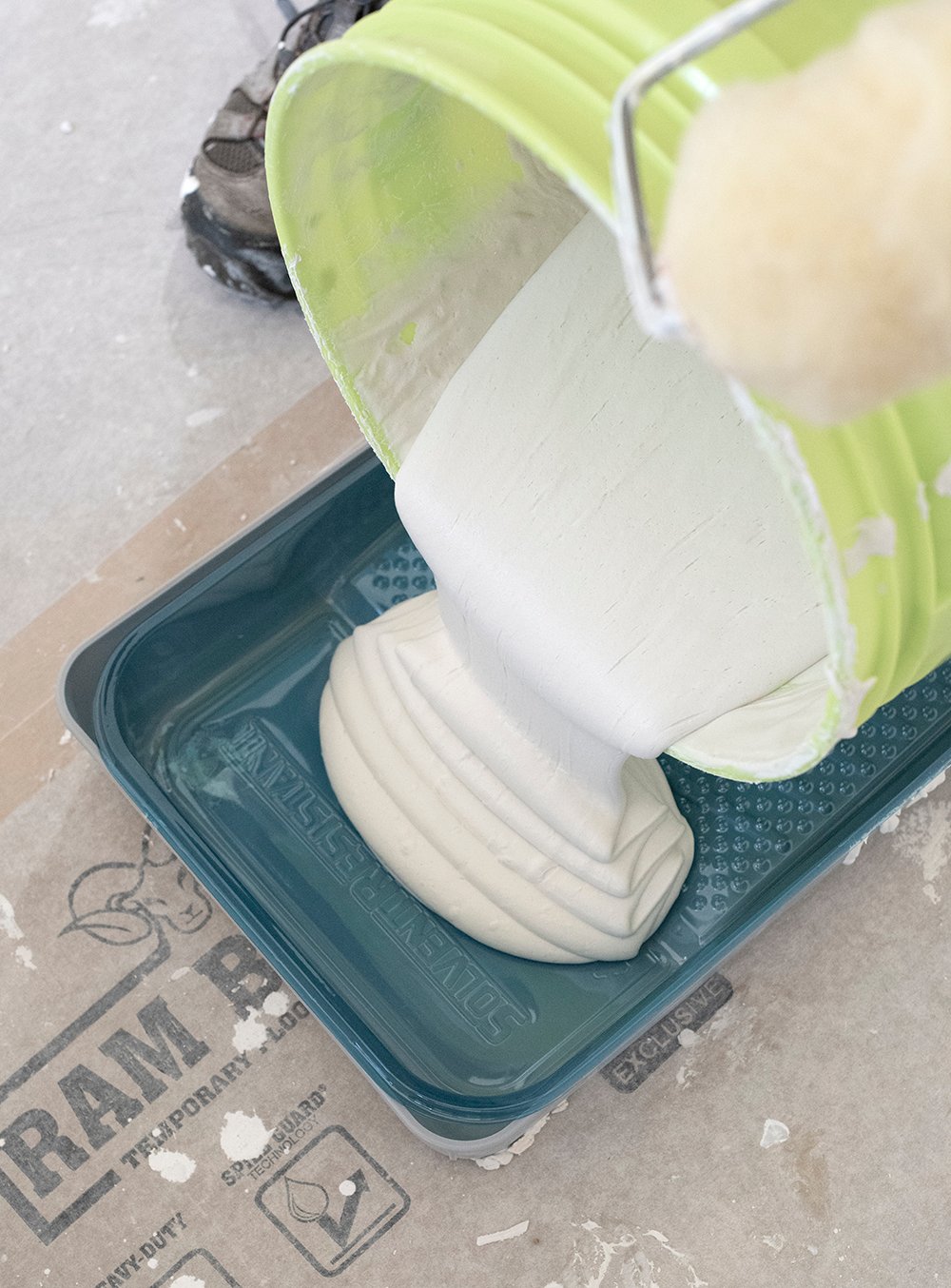

First you’ll mix your joint compound with water. I eyeball (rather than measure) the mix, but it should resemble a thick cake batter consistency. Use your mixer attachment on the power drill until it’s smooth and well combined.

First you’ll mix your joint compound with water. I eyeball (rather than measure) the mix, but it should resemble a thick cake batter consistency. Use your mixer attachment on the power drill until it’s smooth and well combined.

Once you get a good consistency, you’re ready to paint it onto the wall. Using the roller with the 3/4″ nap, roll a section of the wall (I work a 32″ wide section about half the wall height at a time to prevent my mud from drying out too quickly). The texture from the nap should look something like this…

Once you get a good consistency, you’re ready to paint it onto the wall. Using the roller with the 3/4″ nap, roll a section of the wall (I work a 32″ wide section about half the wall height at a time to prevent my mud from drying out too quickly). The texture from the nap should look something like this…

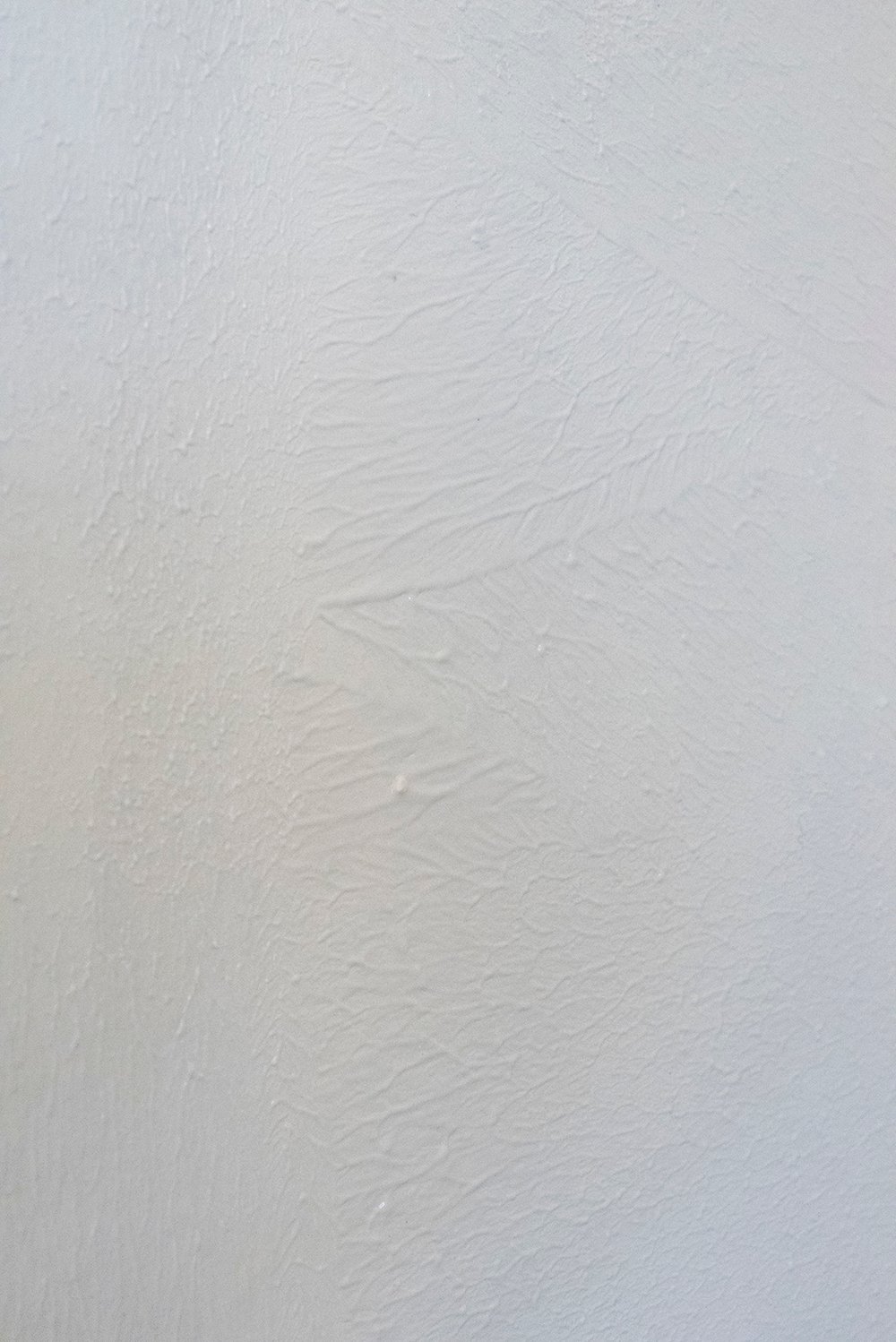

Below is a closer look at the texture the roller leaves behind. It looks kind of scary, as we’re going for perfectly smooth walls- but the key is working in thin, layered coats.

Below is a closer look at the texture the roller leaves behind. It looks kind of scary, as we’re going for perfectly smooth walls- but the key is working in thin, layered coats.

Next, grab your skim coating blade and with firm, even pressure, sweep it across the roller texture. The goal is to remove as much excess joint compound as you can. Think of this as smoothing rather than building up a material. Work in sections and think thin layers!

Next, grab your skim coating blade and with firm, even pressure, sweep it across the roller texture. The goal is to remove as much excess joint compound as you can. Think of this as smoothing rather than building up a material. Work in sections and think thin layers!

Hold the blade at a sharp angle and work quickly, as the mud dries out quickly. The goal is to work in long even sweeps with the blade, without lifting it from the wall. Many walls will require multiple coats. If this is the case, I try to pull my blade one direction (think up and down) for one coat, and then on the second coat I change directions (side to side). Whichever the direction- just make sure it’s a consistent, fluid motion.

Hold the blade at a sharp angle and work quickly, as the mud dries out quickly. The goal is to work in long even sweeps with the blade, without lifting it from the wall. Many walls will require multiple coats. If this is the case, I try to pull my blade one direction (think up and down) for one coat, and then on the second coat I change directions (side to side). Whichever the direction- just make sure it’s a consistent, fluid motion.

Once you have one section of the wall finished, move onto the next, repeating that same process. You will want to clean your blade in between sections, as the joint compound dries quickly and a clean blade works best for that ultra smooth finish.

Once you have one section of the wall finished, move onto the next, repeating that same process. You will want to clean your blade in between sections, as the joint compound dries quickly and a clean blade works best for that ultra smooth finish.

Reload your paint tray with joint compound and start on the next section. Using a bucket with a lid will keep the viscosity consistent for longer as you’re smoothing with the blade. I prefer to mix a large batch, which requires less time and cleaning.

Reload your paint tray with joint compound and start on the next section. Using a bucket with a lid will keep the viscosity consistent for longer as you’re smoothing with the blade. I prefer to mix a large batch, which requires less time and cleaning.

Once the walls are totally dry, you can begin to apply additional coats. Sarah’s office walls were pretty smooth to begin with and I ended up installing three layers. One layer per day. Once the wall are done you will then have to use a corner trowel and apply a coat to the corners for a consistent finish. Give the final coat a full day to dry, then you’ll sand the drywall for that ultra smooth finish. In color, it may not look perfectly even, but as long as it’s super smooth, the primer will do the trick to even the color prior to paint. It should look something like this (don’t be alarmed by color differences)…

Once the walls are totally dry, you can begin to apply additional coats. Sarah’s office walls were pretty smooth to begin with and I ended up installing three layers. One layer per day. Once the wall are done you will then have to use a corner trowel and apply a coat to the corners for a consistent finish. Give the final coat a full day to dry, then you’ll sand the drywall for that ultra smooth finish. In color, it may not look perfectly even, but as long as it’s super smooth, the primer will do the trick to even the color prior to paint. It should look something like this (don’t be alarmed by color differences)…

If you’re looking for a level 5 finish and are using a contractor, it is absolutely something you will need to discuss with them in advance, as it’s a premium finish and not the standard (which is level 4). It really doesn’t use a whole lot more material, however it is very labor intensive. One last thing to note is this tutorial is showing skim coating over a wall that had paint-over-wallpaper. The texture of the wallpaper as well as the seams were visible but it wasn’t in too bad of shape. Skim coating works on textured/popcorn ceilings or any walls that had years of patches and damage to them. This is our perfectly smooth and freshly skim coated wall…

If you’re looking for a level 5 finish and are using a contractor, it is absolutely something you will need to discuss with them in advance, as it’s a premium finish and not the standard (which is level 4). It really doesn’t use a whole lot more material, however it is very labor intensive. One last thing to note is this tutorial is showing skim coating over a wall that had paint-over-wallpaper. The texture of the wallpaper as well as the seams were visible but it wasn’t in too bad of shape. Skim coating works on textured/popcorn ceilings or any walls that had years of patches and damage to them. This is our perfectly smooth and freshly skim coated wall…

I hope those tips and insight proves to be helpful for your next big project! Would you also like tips on sanding? It’s pretty self explanatory and there are lots of ways and tools to help with sanding… I think that’s just personal preference. We splurged and bought a secondhand drywall sander to make quick work of the project, knowing that 70% of our house still needs drywall work. It hooks into our shop vac which means much less dust (which is exactly how I sold Sarah on that purchase, haha). Hand sanding works just as well though! It just requires more time, with a bit more dust, and a lot more elbow grease.

I hope those tips and insight proves to be helpful for your next big project! Would you also like tips on sanding? It’s pretty self explanatory and there are lots of ways and tools to help with sanding… I think that’s just personal preference. We splurged and bought a secondhand drywall sander to make quick work of the project, knowing that 70% of our house still needs drywall work. It hooks into our shop vac which means much less dust (which is exactly how I sold Sarah on that purchase, haha). Hand sanding works just as well though! It just requires more time, with a bit more dust, and a lot more elbow grease.

Let me know if you have any questions in the comment section and I’ll get back with you sometime this week. Thanks for reading and cheering us on with the office reno… it has been a slow go, but we’re cruising along.